Are you protecting your equipment & electronics?

Your equipment is what allows you to be an effective mining operation; without it, you threaten the process and profitability of your business. By protecting critical equipment and the electronics that help run your operation, you can ensure increased productivity and uptime. So, how do you prevent equipment failure? Scrub the air of sulfur and other gaseous contaminants that are causing the electronics and machines to corrode.

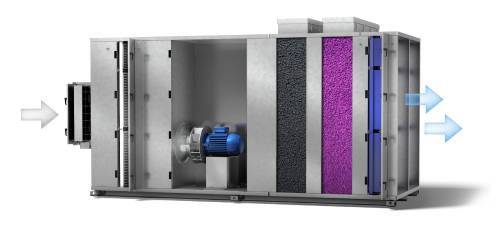

Purafil’s gas phase filtration systems capture and chemically absorb gaseous and harmful (not to mention odorous) contaminants, so you can rely on fully operational equipment and an effective control room with less downtime. As Purafil’s systems clean the air, you’ll come closer to G1 level environments–where corrosion is not a factor in equipment failure–which will give you the peace of mind that your equipment and electronics will require fewer repairs and less downtime.

Confirming Corrosion

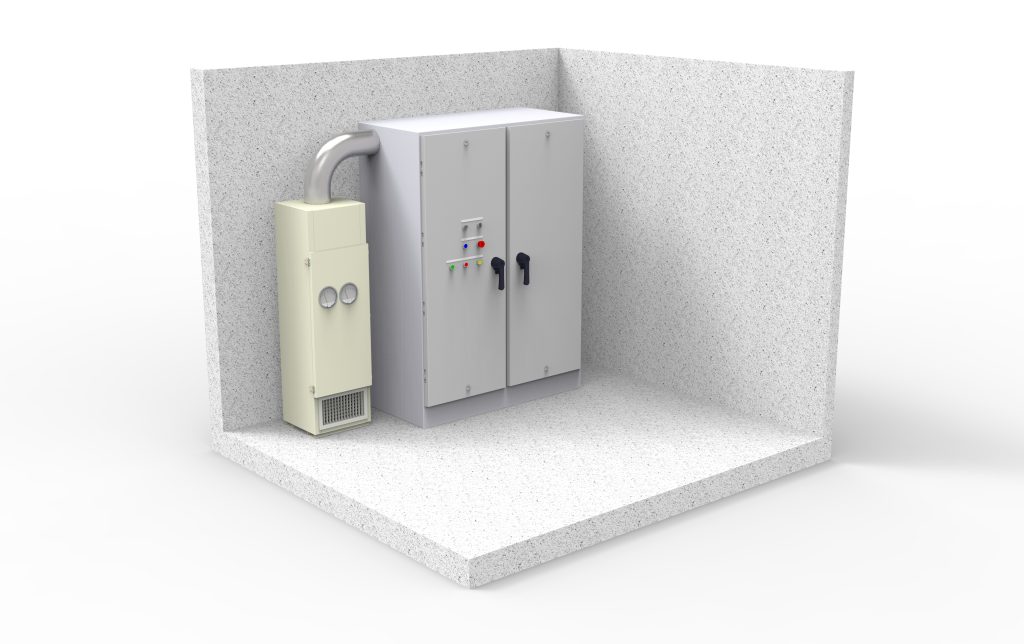

You have equipment rooms throughout your facility that house the motor controls, drives and sensors that allow you to stay up and running. But what happens when your equipment fails and production comes to a halt? Purafil’s Corrosion Classification Coupons (CCCs) help diagnose the problem quickly so you can take corrective action and prevent downtime.

Our coupons include a silver and copper sensor to test the level of corrosion in your facility. After a short exposure time, we’ll test the coupons and determine the severity level. A G1 environment is generally not corrosive to equipment and electronics, whereas a GX environment indicates that your equipment will likely fail due to the high levels of corrosion. Purafil gives you the necessary insights to identify and address corrosion problems.

Monitoring Corrosion

You’ve confirmed that corrosion is what’s wreaking havoc on your equipment, and installed a gas filtration system to remedy the problem, but have you confirmed that it’s working? A monitoring system allows you to maintain a clean environment, free from contaminants, but also indicates when it’s time to replace your media.

Purafil’s OnGuard 4000 continuously measures the air quality (per ISA Standard 71.04-2013) in real time, so you’re confident that you have a corrosion-free environment. It also helps estimate when to replace the media. You can send your media samples into the Purafil lab for testing and a recommended replacement date. Either way, you’re ensuring equipment usability by controlling corrosion.