Prevent mission critical equipment failure by improving air quality in your server room

We don’t know what we don’t know, which is why Purafil offers testing to identify whether or not there’s a corrosion related problem. Electronics are becoming increasingly more advanced and miniaturized. RoHS, commonly called the “lead-free directive”, is intended to reduce the use of hazardous substances in electronic equipment. However, ongoing research has shown that printed circuit boards made using lead-free materials can be more susceptible to corrosion, which could cause damage or failure in your mission critical equipment.

A passive air monitoring program using Corrosion Classification Coupons (CCCs) offers an inexpensive air quality indicator for potential corrosion related failure. It also allows you to predict and prevent corrosion by collecting longterm air quality data. Purafil’s OnGuard® monitor displays real-time data for corrosion, temperature, room pressure, and relative humidity, providing you with a continuous total air quality reading. This allows you to take corrective action before serious damage occurs. Monitoring ensures that your air filtration systems are running at peak efficiency.

Do away with data centre downtime

Purafil follows ISA Standard 71.04-2013 to identify environments, ranking them from G1 to GX. A G1 environment is generally not corrosive to equipment and electronics, whereas a GX environment indicates that your equipment will likely fail due to the high levels of corrosion.

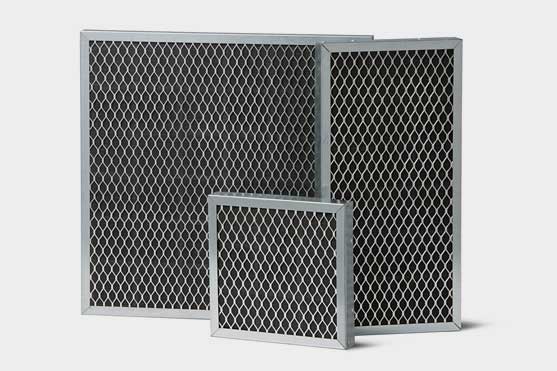

By installing Purafil gas phase filter systems, you’re able to get closer o G1 levels, which means that your equipment and electronics will require fewer repairs, and less downtime.

Eliminate corrosion by eradicating contaminants

Neglecting even low levels of corrosive gases can have costly ramifications; downtime, non-compliance of electronic warranty specifications, ghost signals, circuit board failure and complete failure of electronic components (hard drives, DIMMs, capacitors). Gas phase filtration can be used in conjunction with existing air handling systems or as standalone units with customised media to reduce gaseous contaminants to well below specified levels. Properly applied, gaseous air cleaning also has the potential for energy savings.