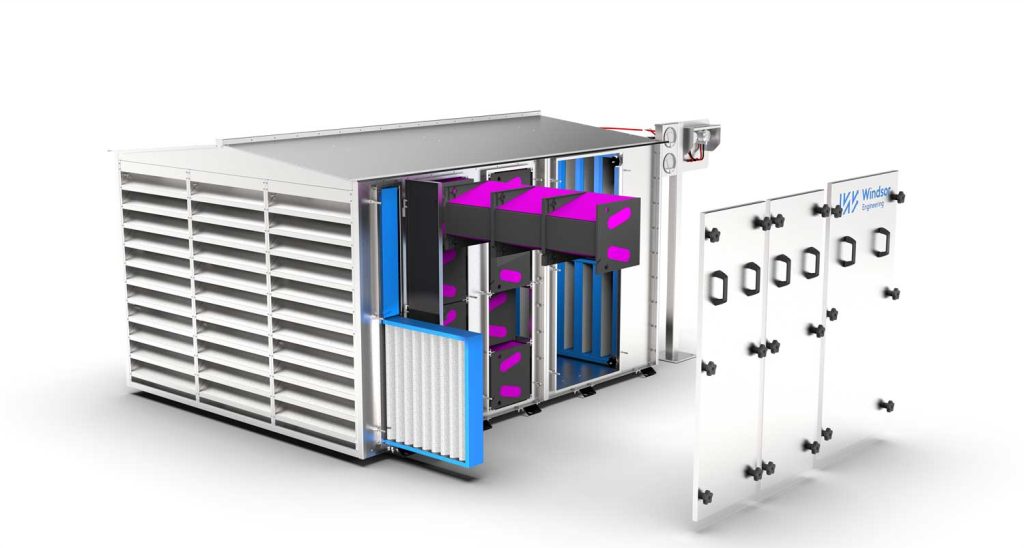

Compressor Intake Filtration

Air compressors provide the compressed air essential in operating pneumatic instruments, control vales and processes throughout industrial plants. Industrial facilities inevitably introduce contaminants into their environment, exposing equipment to the damaging effects of corrosion. Corrosive gases raise the acidity of the compressed air creating aggressive condensate which attacks metal surfaces and leads to vibration and loss of compressor efficiency. To ensure compressors run properly, with a long service life and minimal repairs, it is critical that gaseous contaminants and particulate matter are removed from the intake airstream.

The benefits of the CIF include:

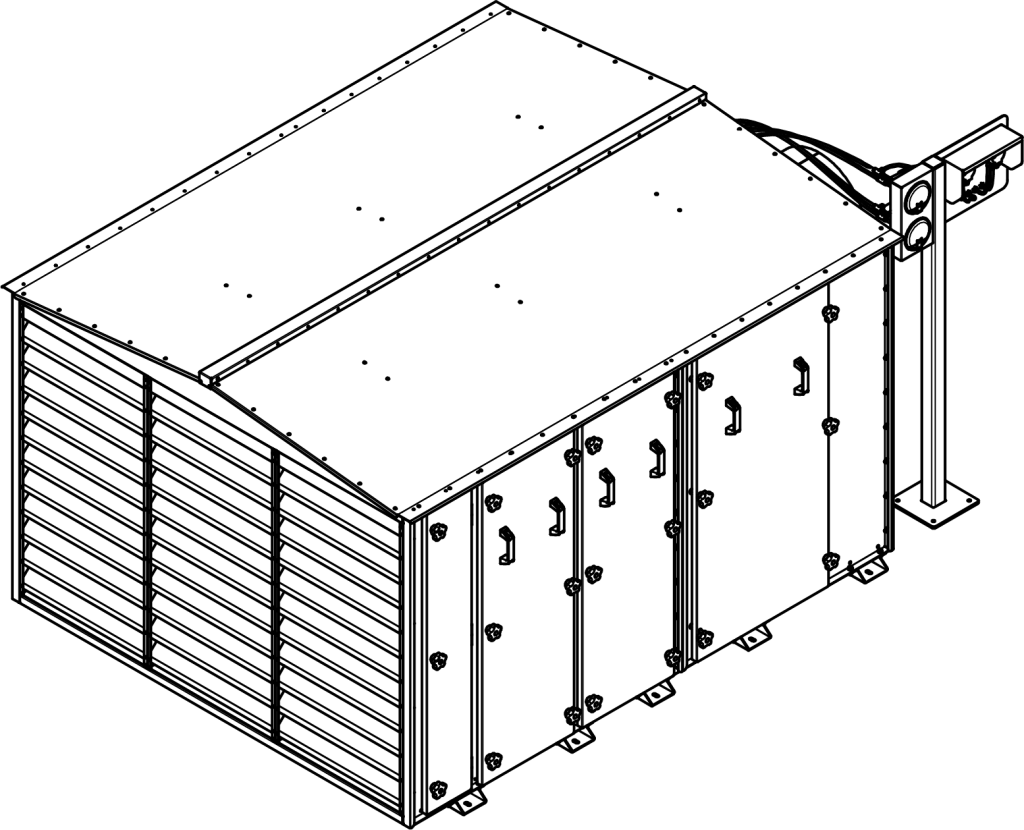

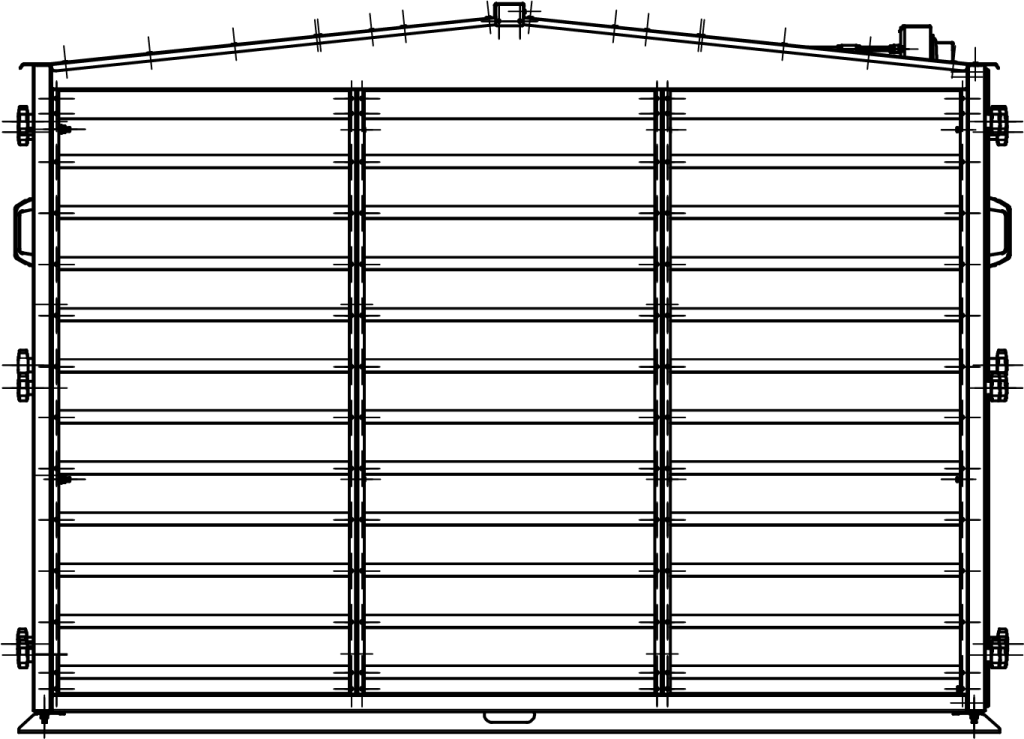

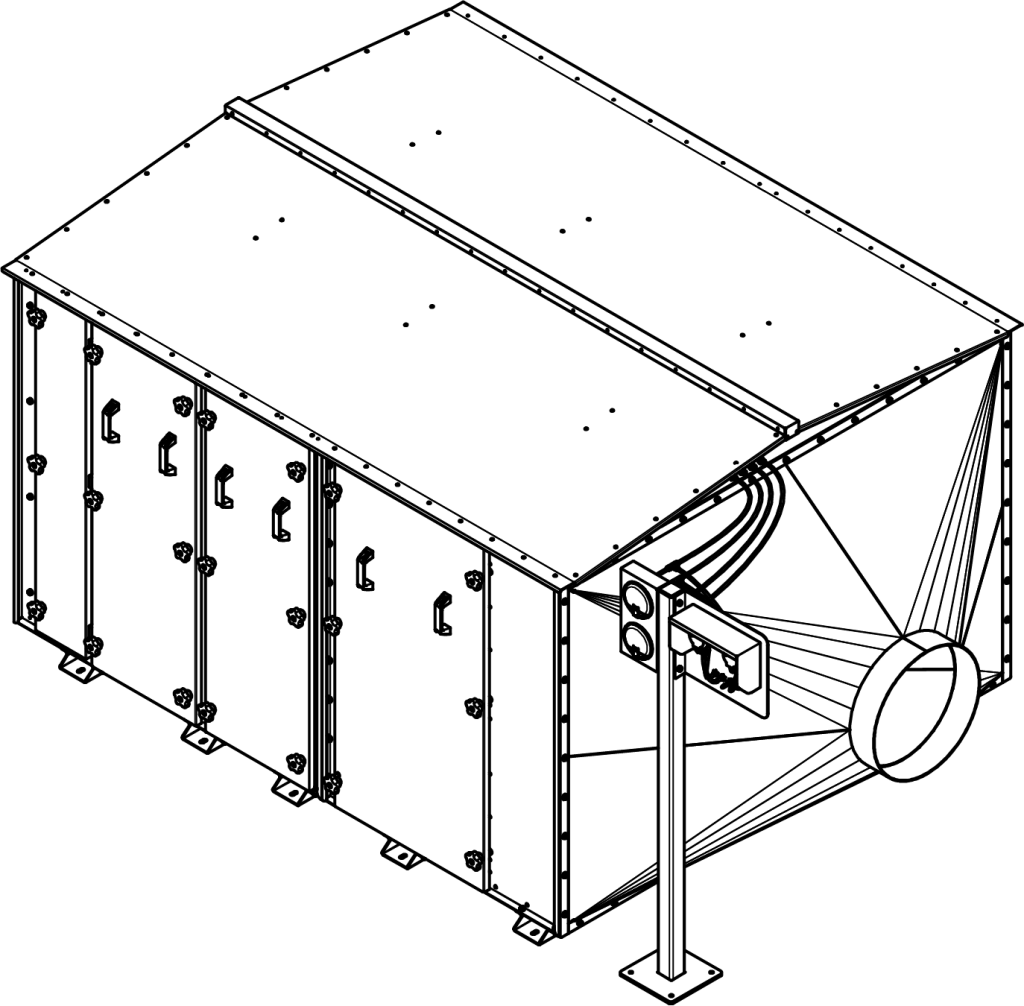

The CIF is a multi-stage, high efficiency air purification system that removes corrosive gases and particulates from the air. Compressor and process downtime is prevented with the CIF, and thousands of dollars of repair costs are saved. The CIF system guarantees high contaminant removal and maintains compressor efficiency.